MAXIMIZING HPHT DRILLING EFFICIENCY & WELL PRODUCTIVITY THROUGH OPTIMAL PROJECT MANAGEMENT

By Dr Michael Gibson

This second section of the three updated Wellideas HPHT (High Pressure High Temperature) Sections shows how Wellideas.co.uk has improved and broadened its HPHT services, particularly now that oil and gas prices have recovered very significantly in recent months. It covers those areas which the Operator did not know about – and neither did the Drilling Contractor – as both had never drilled a HPHT well before. It also portrays those key decision-making areas essential for success.

Today’s high drilling costs – particularly with respect to HPHT wells – necessitate the avoidance of problems, rig down-time, maximum drilling efficiency and maximum hydrocarbon production.

For the latest HPHT Project www.wellideas.co.uk became involved in, the Operator had never been involved with a HPHT well before, and nor had the Drilling Contractors In-Country.

Thus, the project started with the following key areas, which the HPHT Operator had not fully detailed or categorized before the planning phase of the well: –

- Management, Organizational & International Standards (e.g., IADC, API, NACE, SPE Papers, ISO 9001, Best Practices Forums Data etc).,

- Drilling Rig / Drilling Contractor Issues & Interface Documentation, Pressure – Are there any variations or pressure “ramps”?

- Key Technical Issues & Risks,

- Risk Management,

- Project Management.

In addition, there wasn’t a clear statement as regards objectives, viz: –

- What exactly was the primary objective? Were there to be any secondary objectives?

- Was the well to be an Exploration Well to be Plugged and Abandoned after drilling?

- Was the well to be suspended after drilling?

- Could the well, if so designed, become a producer after drilling?

These important key points must be clearly defined before the start of any HPHT Project.

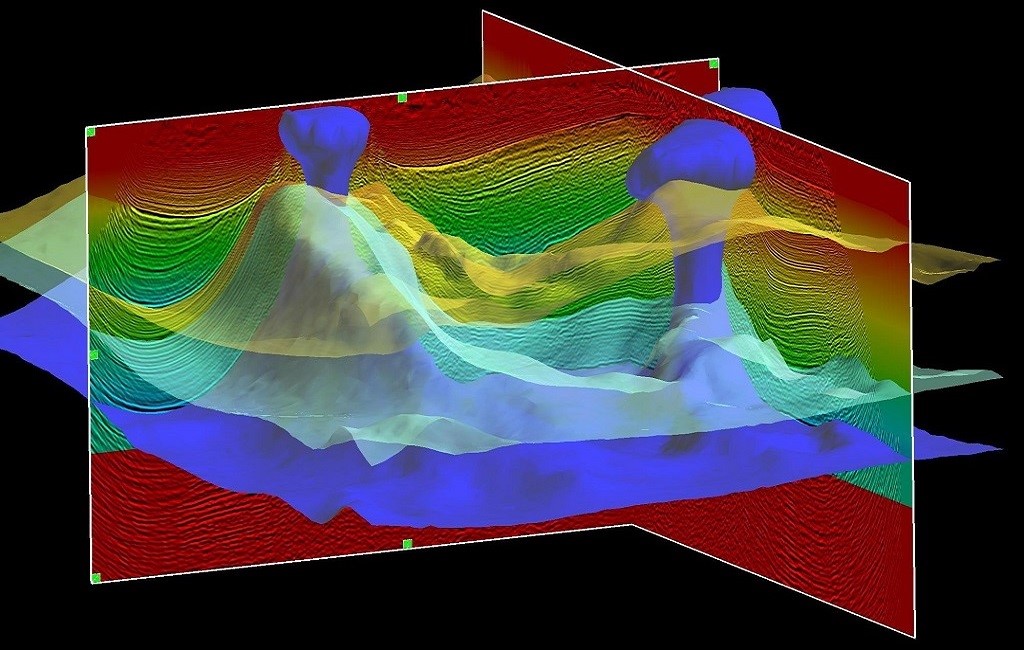

There was also an issue as regards Data. The Seismic Data for HPHT Drilling must be of optimal quality if cost over-runs and drilling problems are to be avoided. The following key points are vital: –

- Clear, unambiguous & definitive data is essential for Optimal Drilling

- Reservoir Target Co-ordinates

- Reservoir Pressure(s)

- Reservoir Temperature(s)

- Hydrogen Sulphide / CO2

- Problematic Geology

- Anticipated AFE

- Anticipated Surface Location etc.

Per the schematic below, any “untoward” potential difficulties must be clearly noted, such as “upthrusts” for example.

Apart from understanding the reservoir geologically and the over-lying geology, it’s also vital to understand the reservoir’s fluids in terms of pressure, temperature, and chemical constituents, such as hydrogen sulphide and sulphate for example, per the below diagram:

The other areas which must be covered are as follows:

- Poor Operator, Drilling Contractor & Service Company Philosophies

- Inadequate well design

- Poor / Inadequate Management Systems

- Poor / Inadequate Well Design Standards

- Poor / Inadequate Operating Philosophies, Procedures & Practices

- Not Understanding the Reservoir and / or Over-lying Geology

- Poor Intra-Departmental and Intra-Company Communication

- Poor Operator / Drilling Contractor & Service Company Interface Documentation

- Poor / Inadequate Contingencies

- Lack of Operator / Drilling Contractor / Service Company Expertise

- Inadequate HPHT Training

- Inadequate / Poorly Executed “DWOP” / “Teamwork” Exercises

- Poor Wellsite Supervision

- Inability of Operator and Drilling Contractor to solve and execute complex well control issues, such as “Cross-flow” and “Underground Blowout” Issues

- Unexpectedly High Pressures / Low Fracture Gradients / High Hydrogen Sulphide / Carbon Dioxide and “Lack of Contingencies”.

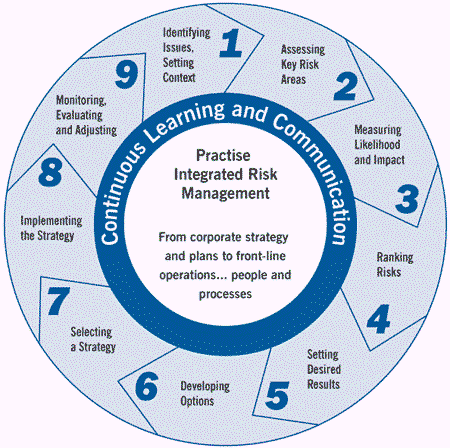

Risk Analysis was also a key area which was missing during the Operator’s initial planning phase. Risk analysis is crucial if “mis-haps” are to be avoided and subsequently managed. Thus, wellideas.co.uk introduced a risk analysis system for the Operator, Drilling Contractor and Service Companies which “reduced risk” to the lowest level possible. The system used is depicted below:

Finally, it’s important to have an “Integral Relationship” with the Drilling Contractor. For, if there isn’t a good working relationship with the Drilling Contractor, the Operator’s endeavours may be fraught with difficulties, problems, and cost over-runs.

In summary, generally, the more information acquired before drilling – the better.

This will lead to not only an effective well, but also a) zero down-time, b) zero NPT (Non-Productive Time) and c) ensure that the well’s objectives are met. It’s vital that the Operator works closely with the Drilling Contractor, the Authorities, the Government – and of course the Service Companies.

Who is Dr Michael T. Gibson?

Dr Michael T. Gibson has 40 years in the Oilfield, working initially as a Drilling Engineer when he studied Mechanical and Offshore Engineering at Bachelor’s, Diploma and Master’s, Degree Level at Robert Gordon’s in Aberdeen under the expert tutelage of Professor Blythe McNaughton. He then went on to take a PHD over an 8-year period whilst working offshore as a Drilling Supervisor.

He began teaching / lecturing full-time 15 years ago in many parts of the world for Oil Companies, Drilling Contractors and Universities and has written the vast bulk of Wellideas’ material, ranging from Manuals, Pocket Handbooks, PowerPoints and Videos for the Classroom and Zoom Meetings, through to E-Learning Modules for distance learning.