MAXIMIZING DRILLING & WELL PRODUCTIVITY THROUGH OPTIMAL DRILLING & COMPLETION TRAINING

By Dr Michael Gibson

This first section of the three updated Wellideas Drilling & Completion Training Sections shows how www.wellideas.co.uk has improved and broadened its Optimised Drilling & Completion Well Training Services, particularly now that oil and gas prices have recovered very significantly in recent months. It covers those key areas which were provided to a major company significantly impressed not just the company itself but the company’s clients. Training was vital after the lay-offs due to CoVid and remains a very high priority due to increasing rig rates and the demand for high productivity due to the prevailing oil and gas prices. Thus, due to their many years of Training experience, www.wellideas.co.uk were utilised to provide Drilling & Well Engineering Training to both provide the material (which was written to IADC, API, SPE & Best Practices Standards on a bespoke basis). This short update covers those training subject areas which were covered – both for the classroom & for E-Learning.

Optimal Drilling & Completion Training really ensures that the well’s design is optimised in terms of safety and cost – and that all objectives are met especially those relating to maximum oil and gas production.

Operators know that a well-trained Drilling & Completion Well Design Team can design wells more safely, cost-effectively, and efficiently than poorly trained teams. Such teams are also able to maximise well productivity, production lifespan and minimise work-over risk. They are also able to design wells to the latest Standards, whether Governmental, Industry Best Practice, API, IADC, Petex, Industry Best Practices etc. Well trained teams are also more likely aware to be abreast of the latest technology and downhole achievements through attending SPE Conferences or reading SPE Papers for example.

Wellideas specialises in Classroom Training, E-Learning Module Provision and Supplementary Methods of Training such as through Internet-based learning.

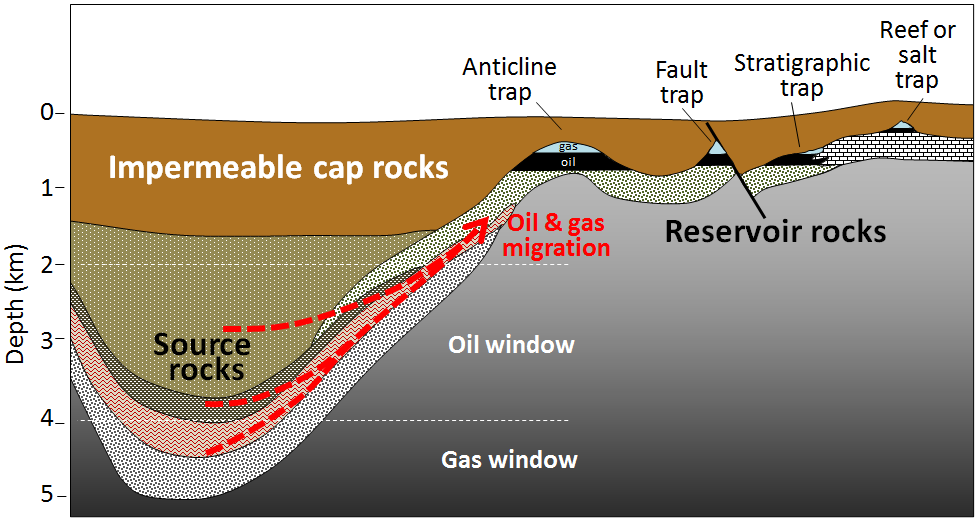

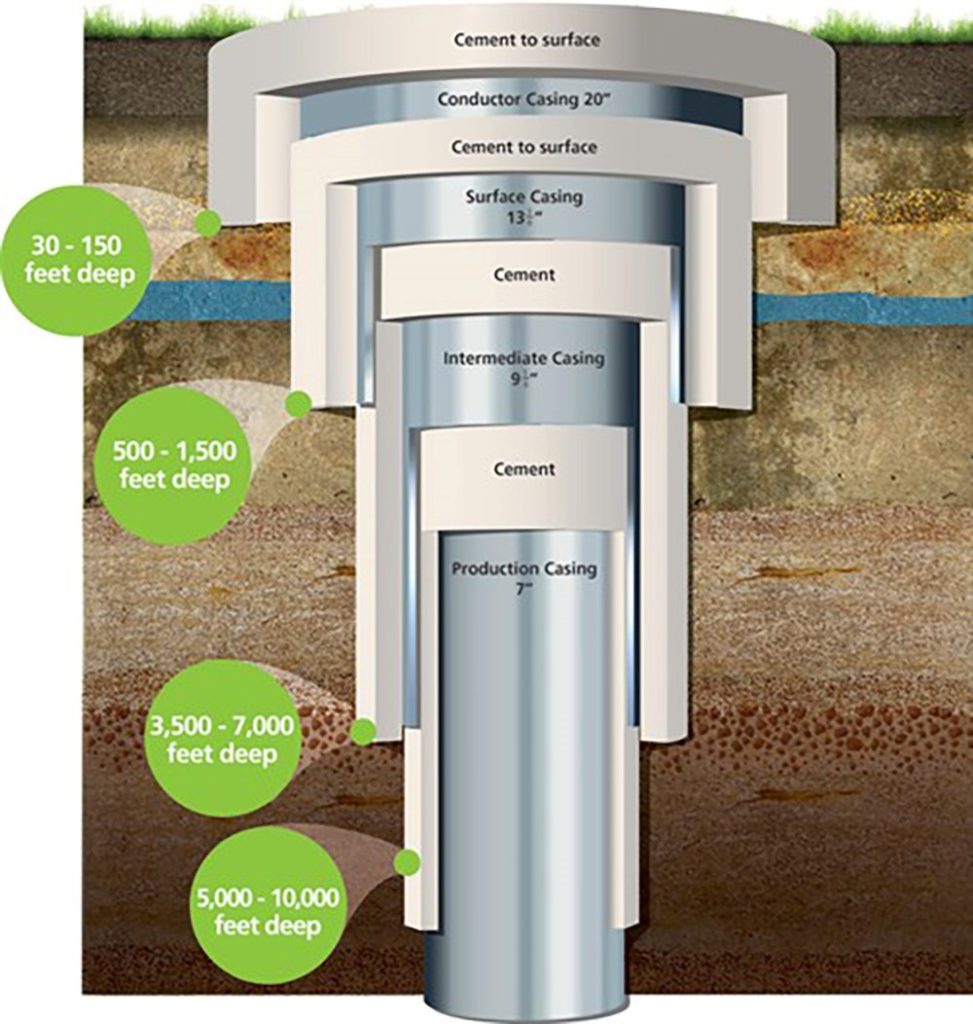

This article references the course of the above title where the course begins with the Role of Optimised Drilling & Completion Well Design & Well Construction, taking the delegates through understanding reservoirs, per several examples, of which the following schematic is but just one. The well cannot be optimally designed if the reservoir and over-lying geology is not understood, so considerable time is spent studying these areas.

The classroom and E-Learning courses then go into the following areas, all per Governmental Regulations, Industry Regulations, API, IADC, Best Practices and accompanying material such as that published by Petex and SPE. In this case update, the client had no worthwhile material of its own, and so www.wellideas.co.uk provided all of the necessary accompanying documentation as well as explanatory videos and texts. The classroom course ended with a Well Design Exercise where the course delegates were broken into teams of four, each with varying skills, and the E-Learning Modules were distributed for further learning or for people who couldn’t make the classroom courses through working offshore for example.

The following areas comprise both the Classroom and E-Learning material: –

- The Role of Optimised Drilling & Completion Well Design & Well Construction

- The Well Design Process (per Government & Industry Standards, API, IADC, Petex, SPE Papers, Industry Best Practices & Technical Works)

- Casing Design (including Well Cat)

- Drilling & Completion Fluids

- Cementing

- Drill Bits & Bit Selection

- Hydraulics & Hole Cleaning

- Drillstring Design

- Surveying & Directional Drilling

- Formation Evaluation

- Rig Equipment & Sizing

- Geological Hazards such as over-pressured zones, weak fractured formations, fractures co-existing within an over-pressured zone, unstable formations / Drilling Problem Avoidance

- Subsea Systems

- Completion Equipment

- Technical Limit Drilling

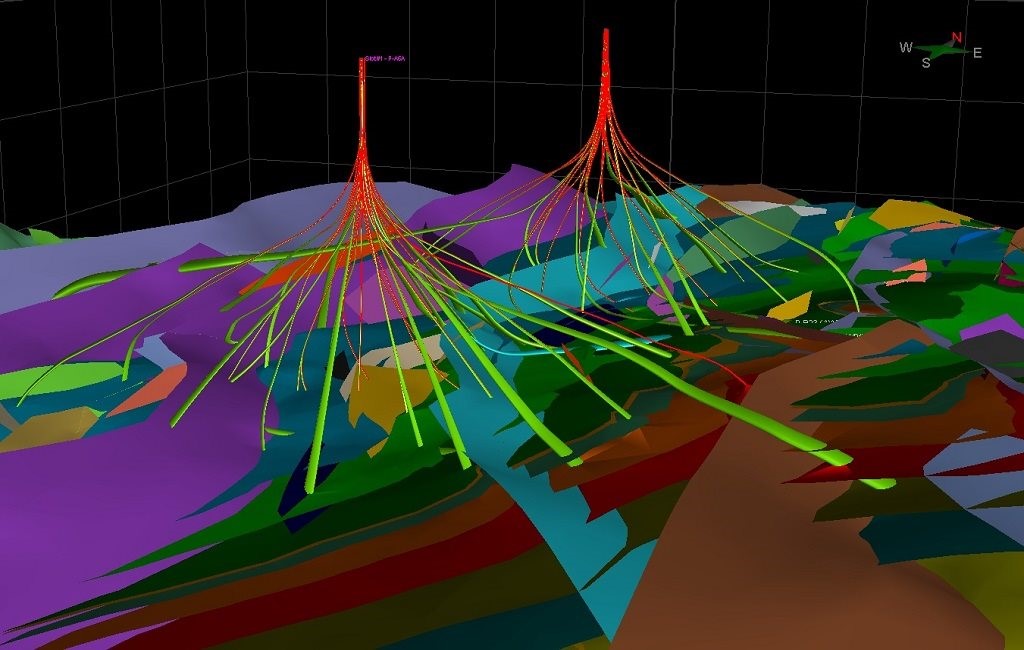

The schematic below depicts one example of a course option, if required, namely multi-well drilling from platforms.

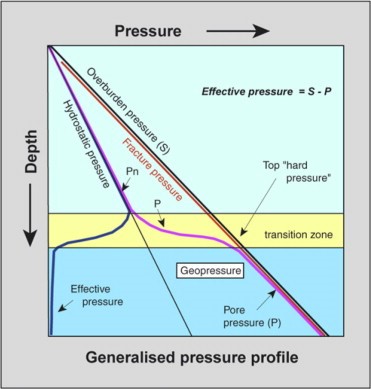

Finally, this Training Program allows for great flexibility due to its combination of Classroom, E-Learning & Internet-based Modules. It can be tailor-made for the pore pressure and fracture pressure profiles of the area (an example is shown in the next schematic) and the casing design and cementation program (an example is shown in the casing schematic) can also be designed per the reservoir, geology, pressures and temperatures.

In summary, excellent training maximises efficiency. This leads not only to a successful well with regards to the meeting of objectives, but it should also be drilled safely, and under budget if the design and planning have been as thorough as possible. Production will also be maximised.

Who is Dr Michael T. Gibson?

Dr Michael T. Gibson has 40 years in the Oilfield, working initially as a Drilling Engineer when he studied Mechanical and Offshore Engineering at Bachelor’s, Diploma and Master’s, Degree Level at Robert Gordon’s in Aberdeen under the expert tutelage of Professor Blythe McNaughton. He then went on to take a PHD over an 8-year period whilst working offshore as a Drilling Supervisor.

He began teaching / lecturing full-time 15 years ago in many parts of the world for Oil Companies, Drilling Contractors and Universities and has written the vast bulk of Wellideas’ material, ranging from Manuals, Pocket Handbooks, PowerPoints and Videos for the Classroom and Zoom Meetings, through to E-Learning Modules for distance learning.