MAXIMIZING HPHT DRILLING EFFICIENCY THROUGH THE USE OF OPTIMAL HPHT DRILLING PRACTICES TRAINING

By Dr Michael Gibson

This third section of the three updated Wellideas HPHT High Pressure High Temperature Sections shows how www.wellideas.co.uk has improved and broadened its HPHT Drilling Efficiency Services, particularly now that oil and gas prices have recovered very significantly in recent months. It covers those areas which the last two Operators and Drilling Contractors Wellideas worked with did not know about since both rigs were “stacked” and many Operator personnel were laid-off due to the downturn following the outbreak of CoVid. Thus, Wellideas.co.uk were brought in as HPHT Drilling Experts to advise both the Operators and The Drilling Contractors. This short update covers those areas which the Operators and Drilling Contractors were unfamiliar with and the key areas which Wellideas were asked to cover during a bespoke combined Operator & Drilling Contractor.

The main “surprise” which Wellideas.co.uk encountered was that neither the Operators nor Drilling Contractors knew that there was a significant difference in Well Control statistics regarding “standard wells” and HPHT wells. Reported, quantified data (IADC / SPE / API and Industry Best Practices) shows that, on average, there is a 1% – 2% risk of a Well Control event on “Standard” wells, whereas the risk of a Well Control event on “HPHT” wells rises dramatically to 5% – 10%. These figures by themselves are quite alarming, since Well Control is so important – hence the creation of the Wellideas.co.uk HPHT Well Control Course.

There are other key factors which are not always taken into consideration by the Operator of Drilling Contractor, such as the temperature ratings of the surface equipment on-board the Drilling Rig.

The following schematic shows an attempt by a Supply Boat to “cool” the rig floor’s surface equipment during a HPHT well control event, such as the choke manifold, glycol injector, driller’s cabin and rig floor for example.

Also, the drilling fluids returning to the surface from downhole will be hot – reservoir temperature minus and “heat exchange” with the formation, casing and cement surrounding the casing etc. This should be modelled in advance.

Apart from HPHT Well Control, Wellideas covered the following key areas in its bespoke HPHT Drilling Practices Training Course:

- General personal competence

- Specific HPHT personal competence

- Management systems

- Operational systems

- Rig systems – Efficiency, Alarm, Flow In Flow Out and Advanced Kick Detection

- BOPE Equipment – Combined Pressure & Temperature Rating and Hydrogen Sulphide

- Shallow gas

- Well design philosophy

- SIWHP at the wellhead

- Assumed Influx Gradient (Exploration well)

- Assumed Influx Volume for Design purposes

- Inadequate HPHT Training

- Geological Hazards such as over-pressured zones, weak fractured formations, fractures Co-existing within an over-pressured zone, unstable formations

- Underground Blowouts Type 1 & 2 / Crossflow

- Unexpectedly High Pressures / Low Fracture Gradients / High Hydrogen Sulphide / Carbon Dioxide and “Lack of Contingencies”.

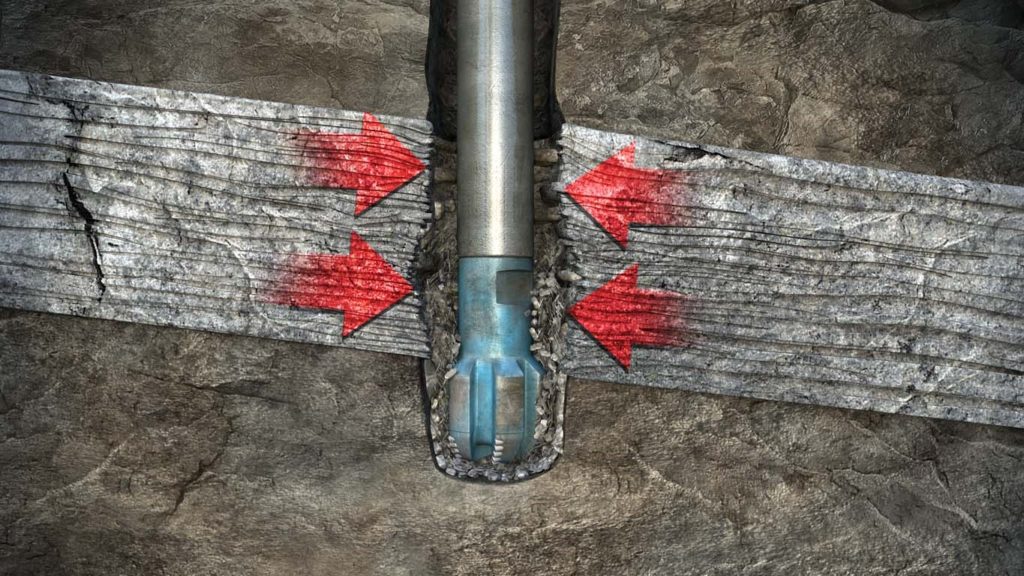

The schematic below depicts one such Geological Hazard, namely over-pressured formation collapsing into the hole which may very well cause the Drilling Assembly to become stick. Due to the very high costs of HPHT wells, this isn’t desirable in the least.

Finally, this combined Training Program allowed both the Operator and the Drilling Contractor (including some Services Companies) to see things from the other’s point of view, which was excellent from an understanding and experience transfer perspective. If there isn’t a good working relationship with the Operator and Drilling Contractor, the well may be fraught with difficulties, problems, and cost over-runs.

In summary, particularly for HPHT Drilling, the more information known prior to spud the better.

This will lead to not only a successful well with regards to the meeting of objectives, but it should also be drilled under budget if the design and planning have been as thorough as possible.

Who is Dr Michael T. Gibson?

Dr Michael T. Gibson has 40 years in the Oilfield, working initially as a Drilling Engineer when he studied Mechanical and Offshore Engineering at Bachelor’s, Diploma and Master’s, Degree Level at Robert Gordon’s in Aberdeen under the expert tutelage of Professor Blythe McNaughton. He then went on to take a PHD over an 8-year period whilst working offshore as a Drilling Supervisor.

He began teaching / lecturing full-time 15 years ago in many parts of the world for Oil Companies, Drilling Contractors and Universities and has written the vast bulk of Wellideas’ material, ranging from Manuals, Pocket Handbooks, PowerPoints and Videos for the Classroom and Zoom Meetings, through to E-Learning Modules for distance learning.