DESIGN & COMPILATION OF A HPHT DRILLING MANUAL

By Dr Michael Gibson

This second section of the Optimised Drilling Practices course written by www.wellideas.co.uk shows the key areas which this newly written section covers. It is essentially entitled “Drill Bits, Bit Selection & Hydraulics” and introduces the delegate to the subject of Optimised Drilling Practices about Drill Bit Selection & Hydraulics Optimisation. In this article, www.wellideas.co.uk describes how and why Drill Bit Selection & Hydraulics are both so important in today’s expensive drilling operations – and regarding the use of the latest use of high technology too. Difficult subject areas are explained using diagrams and Training Videos, and worked examples show how calculations are carried out.

This Module can be taken as a “stand-alone” module or as part of the whole Optimised Drilling Practices Course.

Unless the correct drill bit is used to drill up-coming formations, efficiency will be compromised, and drilling costs will rise. It is thus important to use the correct drill bit – with the associated correct hydraulics – in order to drill efficiently and cost-effectively. The following subject areas are covered in this section in considerable detail: –

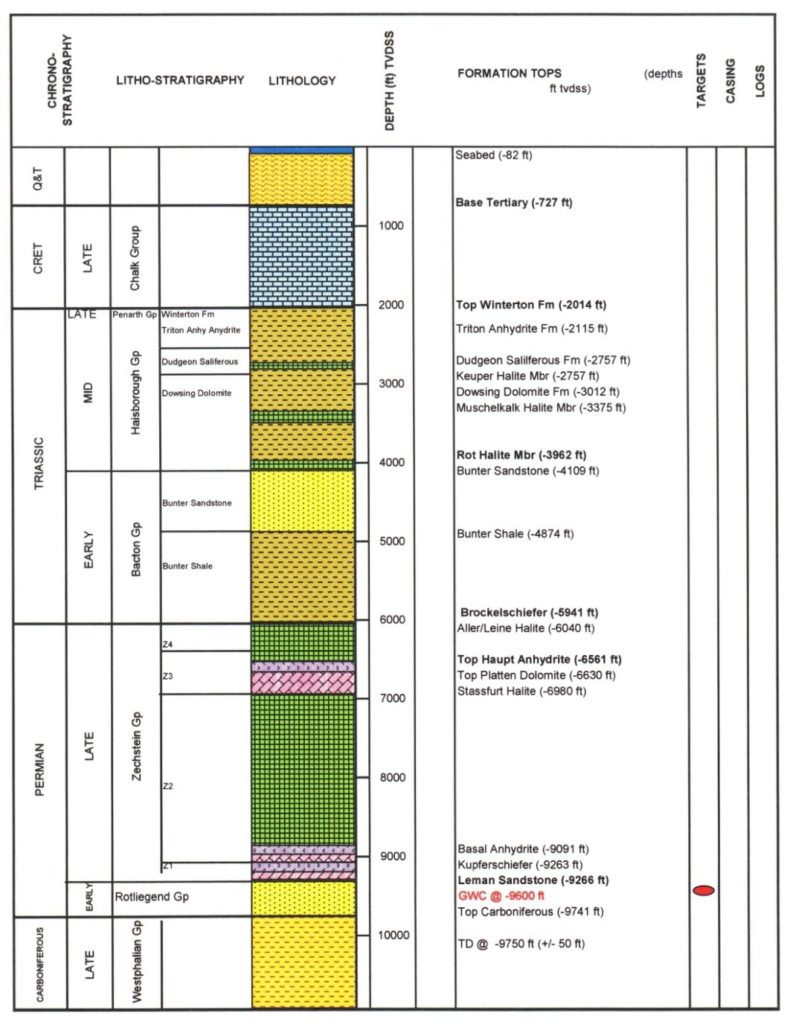

- The Correct Choice of Drill Bit with respect to basic reservoir description & over-lying geology

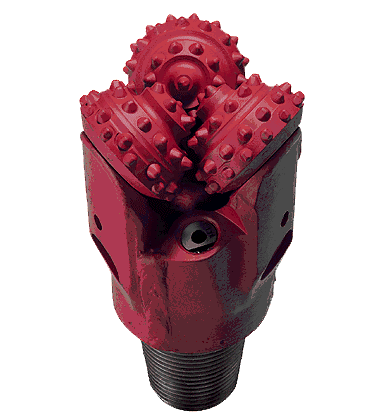

- Tri-cone “Rock Bits”

- Polycrystalline Diamond Bits

- Hybrid Drill Bits

- Impregnated Bits

- Diamond Bits

- How to Reduce Annulus Friction Pressures & Erosion

- The Prevention of Lost Circulation

- Rig Equipment to Maximise ROP and Hole Cleaning

- The Impact of The Drillstring & Downhole Tools Upon ROP

- The Effects of Wellbore Geometry Upon ROP

- The Effects of Very Low Dog Leg Severity Upon ROP

- The Effects of Mud Type Upon ROP

- The Effects of Mud Properties Upon ROP

- The Effects of Hole Cleaning Upon ROP

- The Effects of Solids Control Upon ROP

- Specialised Drill Bits for Directional Drilling

- Specialised Drill Bits for Coring

- Casing “Drill Ahead” Systems

Apart from the written text, the module includes several computer-drawn schematics which would allow someone whose English was not perhaps perfect to see straight away what was being explained.

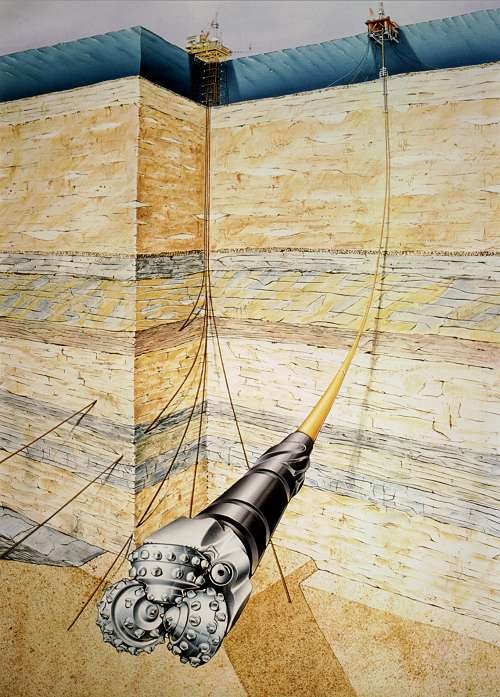

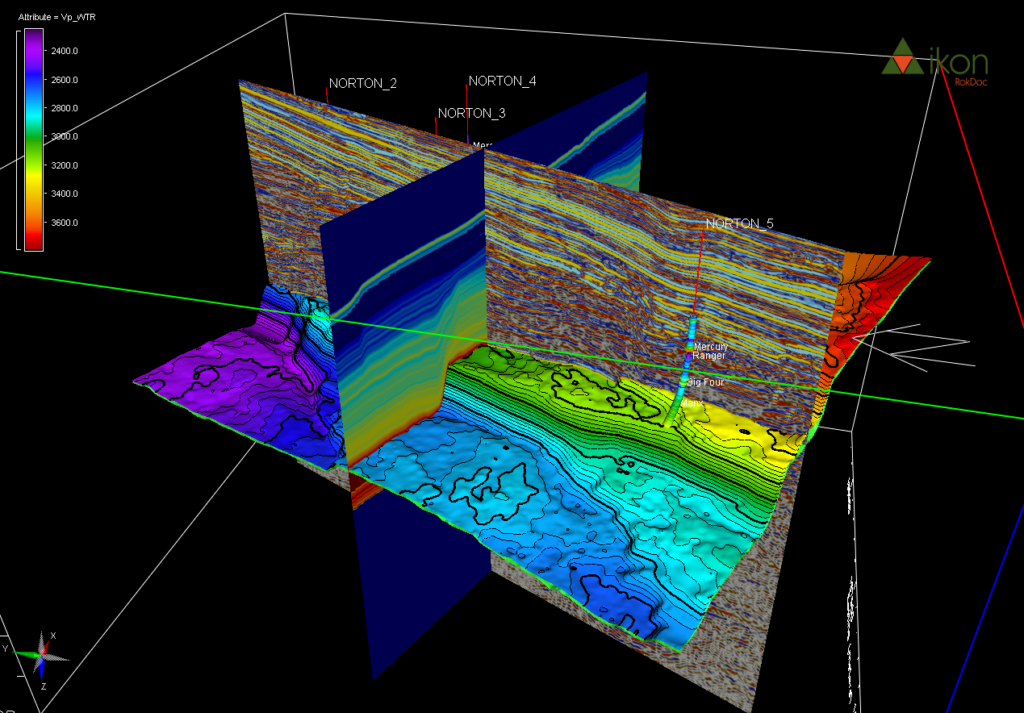

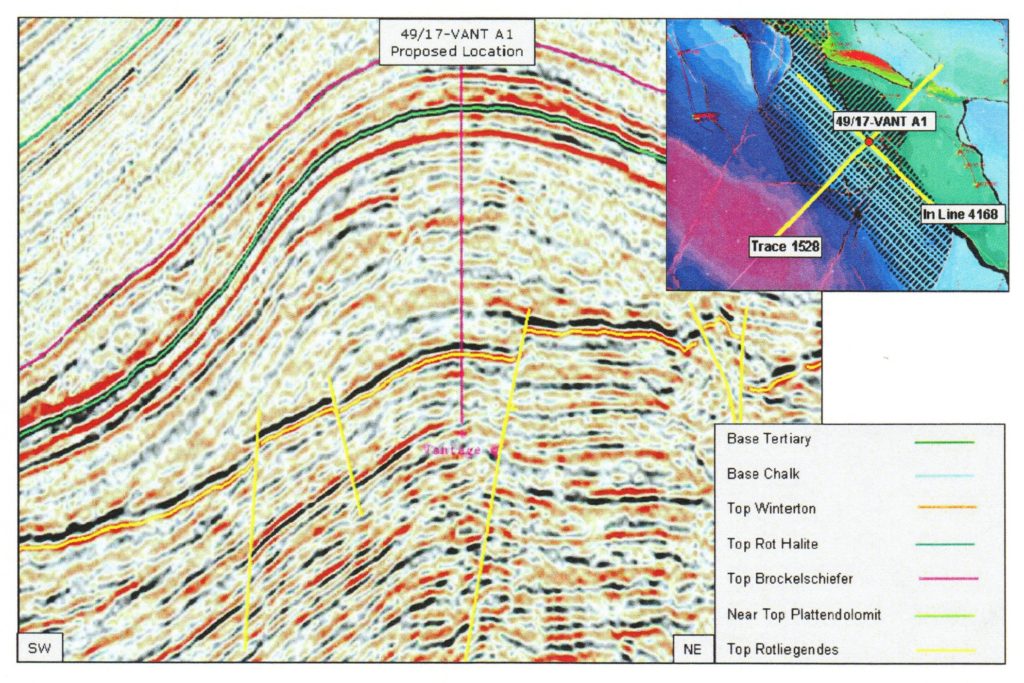

For example, below we can see several schematics which shows how different rock formations demand the choice of different drill bits to maximise their cutting efficiency whist drilling. The reason for optimising the Drill Bit Hydraulics is to ensure that the hole is cleaned – so that maximum ROP can be achieved.

Also, several supportive technical training videos are incorporated into the module, along with photographs etc to aid and maximise understanding.

Where possible, “sub flies” are added to the module, again to maximise understanding, in several areas.

To maximize drilling efficiency, the geology over-lying the reservoir must be truly understood – as well, of course, as the reservoir rock formation itself.

hpht drilling

Apart from understanding the reservoir, seismic also helps us to understand the geology we are going to drill through. This helps us to choose the right drill bits and to maximize drilling operations and performance.

All the principles and standards within this section are based upon the following:

- API

- IADC

- SPE Papers

- HPHT Case Histories

- Drilling Best Practices

- IWCF

- Various Technical Documents from Suppliers / Drilling Contractors etc.

By the end of studying this module, the delegate will have gained a good understanding of The Role of Drill Bits, Bit Selection & Hydraulics.

In summary, this module is an ideal primer to Drilling and Drilling Operations and will help the delegate should he / she study further modules.

hpht drilling

Who is Dr Michael T. Gibson?

Dr Michael T. Gibson has 40 years in the Oilfield, working initially as a Drilling Engineer when he studied Mechanical and Offshore Engineering at Bachelor’s, Diploma and Master’s, Degree Level at Robert Gordon’s in Aberdeen under the expert tutelage of Professor Blythe McNaughton. He then went on to take a PHD over an 8-year period whilst working offshore as a Drilling Supervisor.

He began teaching / lecturing full-time 15 years ago in many parts of the world for Oil Companies, Drilling Contractors and Universities and has written the vast bulk of Wellideas’ material, ranging from Manuals, Pocket Handbooks, PowerPoints and Videos for the Classroom and Zoom Meetings, through to E-Learning Modules for distance learning.